ARK-LA-TEX SPEEDWAY

2020 PROMOD RULES

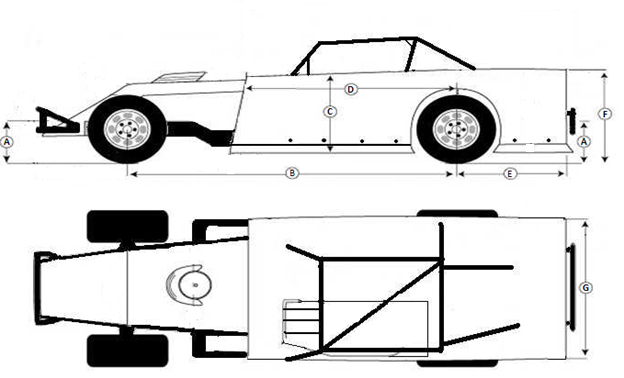

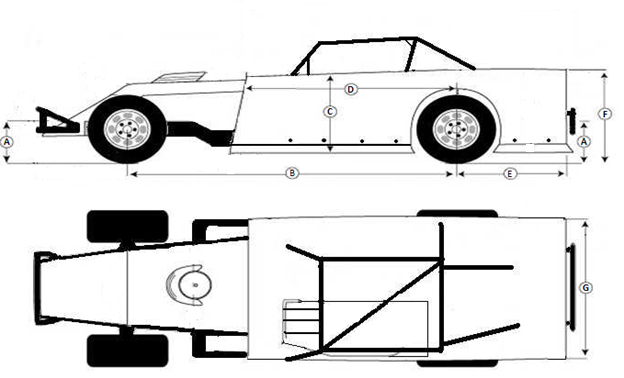

BODY: See diagram. Engine compartment must remain open (no side panels). No panel in front of right door to engine compartment. No inner panels anywhere under body or around suspension. May have a rear spoiler maximum 8 inches in material height and maximum 67 inches wide. Side supports no taller than spoiler 12” maximum length. Must be topless.

DRIVER COMPARTMENT: Must have minimum three windshield bars in front of driver. Minimum 0.125 inch aluminum, or 0.060 inch steel, complete floor pan required. Aluminum high back seat only and must be bolted in, using minimum 0.375 inch bolts, next to left side frame rail and ahead of rear tires. Driver must be sealed off from track, driveline, engine, fuel cell, canisters and pumps. No driver-adjustable devices allowed while car is in competition except brake adjuster. No mirrors of any kind.

FRAME: American rear-wheel drive passenger car frame only. Frame must be full and complete, cannot be widened or narrowed, and must be able to support roll cage on both sides, exceptions are: weight jack in original center line of spring tower allowed; frame may be cut a maximum 36 inches forward from center of rear end housing; horns may be removed in front of steering box front crossmember may be notched and boxed for radiator and/or steering clearance. Minimum wheelbase 108 inches, maximum 112 inches, both sides. Maximum overall width shall not exceed 82 inches from outside of tire to outside of tire. For cars using OEM rear suspension design, rear of frame behind rear tires no further forward than one inch behind factory seam, may be replaced with two inch by three inch steel tubing with 0.095 inch wall thickness.

ROLL CAGE: Must consist of continuous hoops, minimum 1.50 inch O.D. tubing, with minimum wall thickness of 0.095 inch for main cage, frame mounted in at least six places. Roll cage must be securely supported and braced with minimum one cross bar in top halo. Foot protection bar required. Main cage no further forward than rear of engine. All bars forward of cage must be lower than hood. All driver side door bars and uprights must be minimum 1.5 inch O.D. Minimum three driver side door bars, parallel to ground and perpendicular to driver, and welded to front and rear of roll cage. Passenger side must have at least one cross door bar, horizontal or angled, minimum 1.25 inch O.D. with 0.083 inch wall thickness, and one top door bar, minimum 1.5 inch O.D. with 0.083 inch wall thickness. Steel door plate, 18 gauge or 0.049 inch minimum thickness, must be securely welded to outside of driver side door bars.

FRONT SUSPENSION: All components must be steel, unaltered OEM, in OEM location, and replaceable by OEM parts, exceptions are: tube-type upper A-frames and mounts can be moved; OEM replacement stamped steel lower A-frames; rubber, nylon or steel lower A-frame bushings, no offset or bearing type. Lower A-frames must be right and left, and of same design. Lower A frame mounts and bolt holes on frame must be in OEM location.

STEERING: No rack and pinion. All components must be steel, unaltered OEM, in OEM location, exceptions are: outer tie rod end and adjustment sleeve may be replaced by a minimum 0.625 inch steel rod end and steel tube; spindles can be ground for brake caliper clearance only; bolt on spindle savers allowed. Spindles must be right and left, and of same design. OEM Idler arm, pitman arm, and center link must match frame.

SHOCKS: One steel, nonadjustable, unaltered shock per wheel only. No shocks allowed on screw jacks. No external or internal bumpers or stops. No coil over, bulb type body, air, or remote reservoir shocks. No Schrader valves or bladder type valve allowed.

REAR SUSPENSION: One coil or leaf (rear) spring per wheel only. Minimum 4.5 inches O.D., nonprogressive coils only. No torsion bars, air bags or inner liners. No aluminum or titanium components allowed. All mounts and brackets must be welded or bolted solid. Coil springs must remain vertical and over center line of rear-end housing. No coil-over eliminators allowed. Rear shocks cannot be mounted on control arms. Must utilize one of the following designs: (A) Aftermarket three link design requirements: Must use 15 inch minimum, 24 inch maximum lower control arms measured center to center. Must use one upper control arm, solid tube only. Must use minimum 21 inch panhard or J Bar measured center to center. Lower spring perch must be welded to rear-end housing must be center over axle tube. No floating or bearing rear spring perches/cups allowed. (B) Leaf spring design requirements: Must use leaf springs with no additional suspension components besides one shock per wheel. Adjustable aluminum lowering blocks allowed. (C) OEM stock design requirements: Rear crossmember, control arm mounts and bolt holes on frame must be in stock location. Springs must remain in stock location. Lower spring perch must be welded to rear-end housing.

REAR END: Any steel approved OEM passenger car or truck non-cambered rear end (housing and carrier) allowed, must be centered in chassis. All components must be steel, except lowering blocks, axle cap, and drive flange. Safety hubs (floater) allowed. No quick change devices. No Detroit Lockers, Gold Tracks or any other types of traction control devices.

BUMPERS: Steel bumpers must be on front and rear. Rear bumper must be constructed of solid square, or minimum 1.25 inch O.D. tubing with 0.095 wall thickness, and no wider than five inches outside of rear frame rails. If wider than five inches outside rear frame rails, must be capped and bent forward 90 degrees, or constructed in a loop design. Must have at least one upright, minimum 1.25 inch with 0.065 wall thickness, from bumper to fuel cell guard. Two-bar front bumper must be minimum 1.25 inch O.D. tubing with minimum 0.065 wall thickness (maximum 0.095 inch) mounted frame-end to frame-end, no wider than width of material outside frame horns and with bottom loop parallel to ground. Top bar must be directly above bottom bar, minimum 6.5 inches apart, measured center to center.

TIRES/WHEELS: Must use unaltered Hoosier Asphalt pulloff F45. May also run Hoosier F40, F45, (1070), F50, F56 or AR-152 on front. No re-caps allowed. Must durometer 60 or higher, subject to inspection any time before or after the race. No grooving, siping, needling, metal grinding disc, treating, softening, or wrapping in plastic allowed. Deglazing with sand paper disc ONLY allowed, but cannot leave any grinding marks and is subject to inspection before or after race. All wheels must be steel, 8” or 10” wide. No bleeder valves, bead lock, on right rear only. Must use only steel bolts. Must use minimum one inch O.D. Steel lug nuts. Mud plugs and wheel covers allowed ONLY on the right rear. Wheel cover must be plastic, be bolted, no Dzus fasteners, the ring that holds the wheel cover must be welded to the wheel in at least three places.

BRAKES: Must be steel approved OEM, operative three or four wheel, drum or disc. Must maintain minimum OEM dimensions for hubs/rotors and OEM steel calipers only, cannot be lightened. Bolt pattern may be changed. Larger studs allowed. Rear rotors may be aftermarket 0.81 inch thickness (new). Vented rotors only, no scalloped or ceramic coated rotors. One proportioning device allowed front to rear only. Rear caliper brackets must be welded or bolted solid to rearend housing. No floating calipers.

EXHAUST: Round tube headers only. All primary header tubes must enter directly into one collector. No tri-Y headers.

FUEL SYSTEM: Racing fuel cell required, maximum 32 gallon capacity must be in minimum 20 gauge steel container. Cell must be securely mounted behind rear axle. Must mount with minimum two solid steel straps around entire cell, two inches wide and 0.125 inch thick. Fuel cell vents, including cap vent, must have check valves. If fuel cell does not have aircraft style positive seal filler neck/cap system - a flapper, spring or ball type filler rollover valve is required. Any single carb. Gas or methanol. No fuel injection. No ICT(individual cylinder tuning) carbs.

GAUGES/ELECTRONICS: 12 volt ignition system only. No electronic traction control.

TRANSMISSION: Steel drive shaft only, minimum two inch diameter and painted white. Steel slip yokes only. 360degree drive shaft loop required and must be constructed of at least 0.25 inch by two inch steel, or one inch tubing, mounted six inches back from front U-joint. With engine running and car in still position, driver must be able to engage car in gear and move forward, then backward. No ‘in and out’ boxes or quick change devices allowed.

ENGINE COMPARTMENT: Rear of engine (bellhousing flange) must be mounted at least 72 inches forward from centerline of rear axle. Stock rear suspension mounts may be at 70”. Radiator must be mounted in front of engine. Cast Iron block ONLY. ‘Wet’ sump oiling system only. Steel oil pans only. If you run aluminum heads must ad 25lbs. in front of motor plate.

WEIGHT: Minimum weight limit of 2,400 lbs. stock rear suspension cars (limiteds) must weight minimum of 2,300 lbs. Weights must not be used in driver compartment or outside body. All weights must be securely mounted with at least two 0.5 inch bolts, painted white with car number on it. No titanium, magnesium, stainless steel or carbon fiber components. Solid steel fasteners only.

A. 23”

max. 16” min. (ground to center of bumpers, front and

rear)

B. 112”

max. 108” min.

C. 31”

max. 22” min.

D. 72”

max or not past back of block at top. Left side may extend forward to

cover foot box if necessary.

E. 48”

max.

F. 41”

max.

G. 67”

max. measured at top of interior deck.